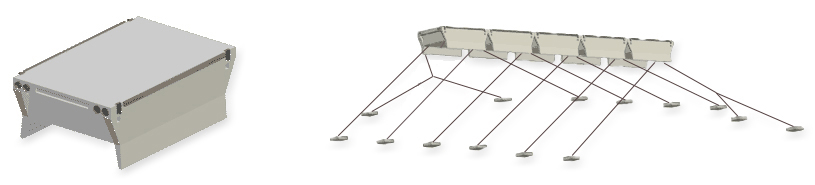

From the Uni-Module floats themselves, to the anchoring systems that secure them,

each of our products are designed, manufactured, assembled and installed by us.

Baypoint Lakefront Condo’s

Lake of the Ozarks, MOFloating Concrete Wave Attenuator

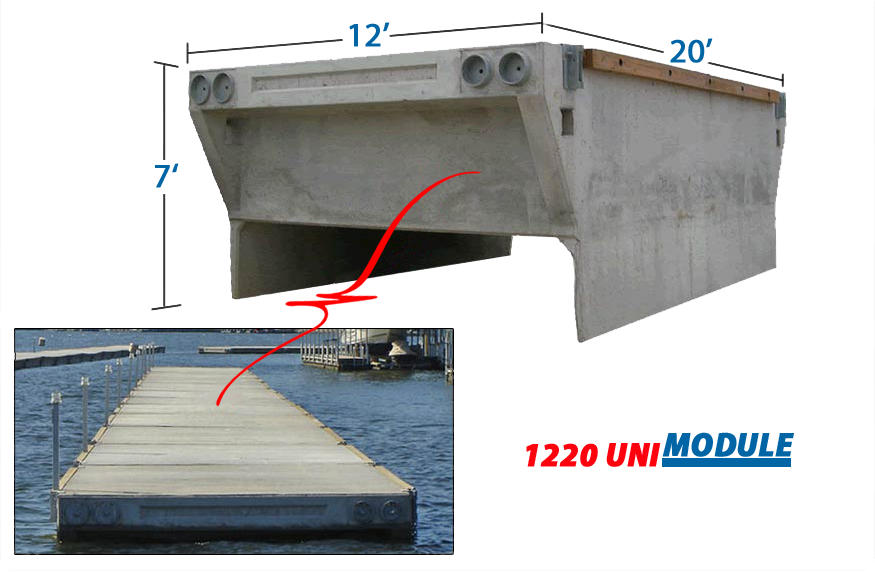

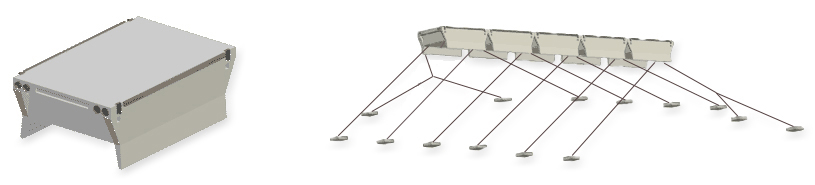

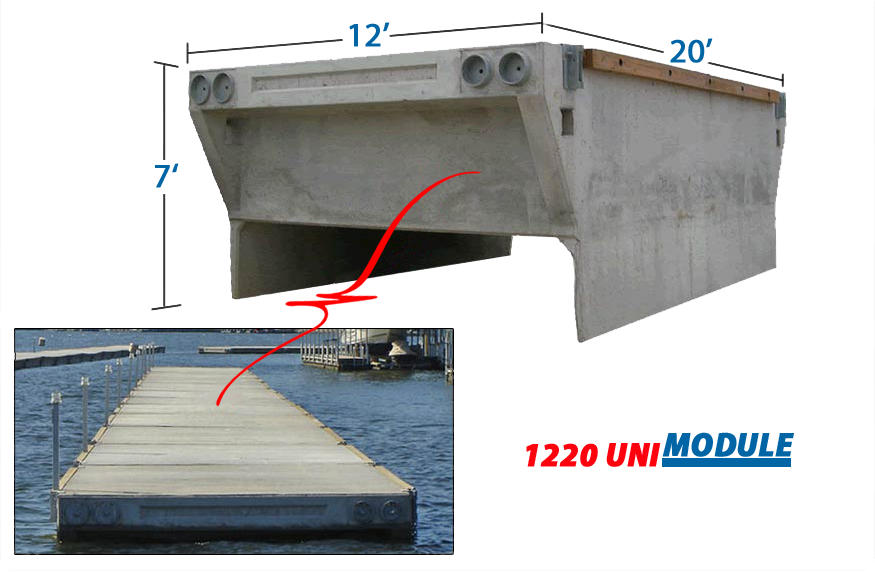

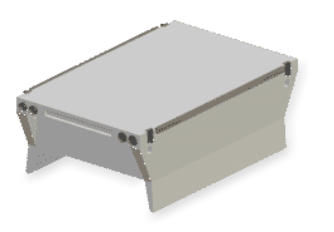

Each monolithic superior wave attenuator 12x20 Uni-Module is manufactured and inspected at our plant, then shipped to marinas collectively

where they are assembled to make our floating breakwaters. Each with the following features:

•

Heaviest - about 2,000 Lbs. Per Running Foot.

•

Widest - 12 Feet 7 Inches With Treated Side Whalers.

•

Deepest - 7 Feet about 40,000 Lbs. Per 20 Foot Section Including Anchor Pull Down Weight.

•

Competitively Priced.

•

Concrete Encapsulated On All 6 Sides (Yes, Underneath Also!).

•

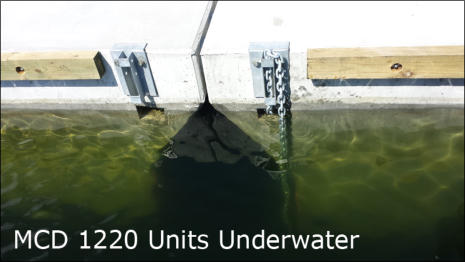

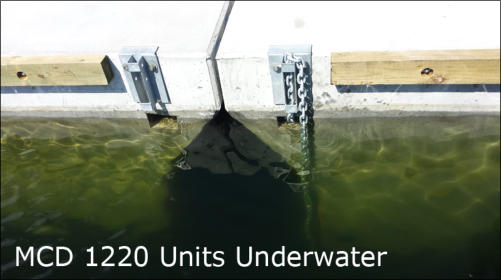

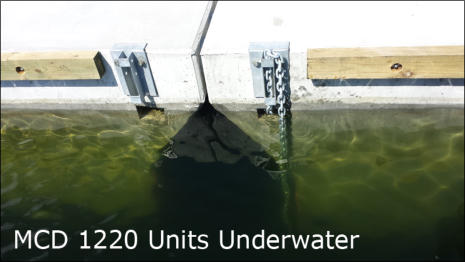

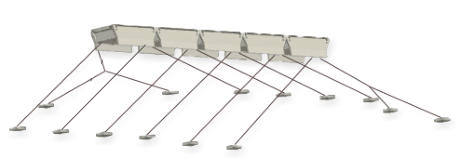

Adjustable Chain And Rope Anchor System, Designed To Absorb Wave Energy.

•

Also Available: Adjustable Marine Winches And Cable, or Pile Guides.

•

Hydraulically Post-Tensioned Galvanized Cable System.

•

Freeboard - about 14-24 inches per 1220 unit and can vary joint to joint and ends.

•

Environmentally Friendly and Prevents Shoreline Erosion.

•

Manufactured Without Legs For Shallow Water Or Near Shore Applications.

•

Brushed Surface That Provides A Non - Slip Walking Surface

•

Marine Polystyrene Core And A Outer Reinforced Concrete Shell.

•

Four Hydraulically Post-Tensioned Cables Run Lengthwise Through PVC Tubing, Molded Into Each Section, To Protect The Cable Against Corrosion.

•

All Post - Tensioned Cables And Components From End To End Are All Above Water.

•

No Bolts, Pins Or Welded Connection Joints.

•

All Galvanized Steel Is Above Water.

•

A Proven Patented Connection Joint That Eliminates Exposure To Sunlight And Water.

•

Four Flexible Couplers Are Between Each Unit.

•

Chain Stands On The Sides For Easy Water Fluctuation Adjustments, And Are 12’ Apart For More Leverage, Stability And Clearance For Boat Traffic.

•

Solar Powered Flashing Amber Lights Standard Every 30 Feet.

•

Utility Options Also Available.

•

Designed As A Commercial Marina Dock System That Has An Option To Add Four Foot or Eight Foot Finger Piers.

•

4 Chain/Cable Anchor Bracket Locations Every 20 Feet.

•

Long Life Span With Our Three-Year Limited Flotation Warranty.

•

Pressure-Treated 4" by 6" Wooden Side Whalers Are Added As A Standard Protection Feature.

•

Post - Tensioning of Continuous Straight Lines.

The 20 Foot Precast Concrete Construction Allows for Anchors To Be Installed Every 20 Feet In Both Directions, Making It The Most Reliable

System Available.

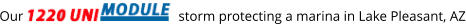

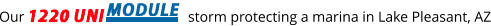

OUR WAVE ATTENUATOR 1220 UNI-MODULE HAS A PROVEN STORM TRACK RECORD AND HAS OUT PERFORMED AND OUTLIVED ANY PLASTIC,

WOOD, ALUMINUM, STEEL OR ANY COMBINATION OF MATERIALS THAT ARE LESS THAN AN ALL CONCRETE PRODUCT.

40,000 lbs.

per unit

Built Stronger, Last Longer

From the Uni-Module floats themselves, to the anchoring systems that secure them,

each of our products are designed, manufactured, assembled and installed by us.

Built Stronger, Last Longer

Baypoint Lakefront Condo’s

Lake of the Ozarks, MOFloating Concrete Wave Attenuator

Each monolithic superior wave attenuator 12x20 Uni-Module is manufactured and inspected at our plant, then shipped to marinas collectively where they are assembled to make

our floating breakwaters. Each with the following features:

•

Heaviest - about 2,000 Lbs. Per Running Foot.

•

Widest - 12 Feet 7 Inches With Treated Side Whalers.

•

Deepest - 7 Feet about 40,000 Lbs. Per 20 Foot Section Including Anchor Pull Down Weight.

•

Competitively Priced.

•

Concrete Encapsulated On All 6 Sides (Yes, Underneath Also!).

•

Adjustable Chain And Rope Anchor System, Designed To Absorb Wave Energy.

•

Also Available: Adjustable Marine Winches And Cable, or Pile Guides.

•

Hydraulically Post-Tensioned Galvanized Cable System.

•

Freeboard - about 14-24 inches per 1220 unit and can vary joint to joint and ends.

•

Environmentally Friendly and Prevents Shoreline Erosion.

•

Manufactured Without Legs For Shallow Water Or Near Shore Applications.

•

Brushed Surface That Provides A Non - Slip Walking Surface

•

Marine Polystyrene Core And A Outer Reinforced Concrete Shell.

•

Four Hydraulically Post-Tensioned Cables Run Lengthwise Through PVC Tubing, Molded Into Each Section, To Protect The Cable Against Corrosion.

•

All Post - Tensioned Cables And Components From End To End Are All Above Water.

•

No Bolts, Pins Or Welded Connection Joints.

•

All Galvanized Steel Is Above Water.

•

A Proven Patented Connection Joint That Eliminates Exposure To Sunlight And Water.

•

Four Flexible Couplers Are Between Each Unit.

•

Chain Stands On The Sides For Easy Water Fluctuation Adjustments, And Are 12’ Apart For More Leverage, Stability And Clearance For Boat Traffic.

•

Solar Powered Flashing Amber Lights Standard Every 30 Feet.

•

Utility Options Also Available.

•

Designed As A Commercial Marina Dock System That Has An Option To Add Four Foot or Eight Foot Finger Piers.

•

4 Chain/Cable Anchor Bracket Locations Every 20 Feet.

•

Long Life Span With Our Three-Year Limited Flotation Warranty.

•

Pressure-Treated 4" by 6" Wooden Side Whalers Are Added As A Standard Protection Feature.

•

Post - Tensioning of Continuous Straight Lines.

The 20 Foot Precast Concrete Construction Allows for Anchors To Be Installed Every 20 Feet In Both Directions, Making It The Most Reliable System Available.

OUR WAVE ATTENUATOR 1220 UNI-MODULE HAS A PROVEN STORM TRACK RECORD AND HAS OUT PERFORMED AND OUTLIVED ANY PLASTIC, WOOD, ALUMINUM, STEEL OR ANY

COMBINATION OF MATERIALS THAT ARE LESS THAN AN ALL CONCRETE PRODUCT.

40,000 lbs.

per unit

Baypoint Lakefront Condo’s

Lake of the Ozarks, MOFloating Concrete Wave Attenuator

Each monolithic superior wave attenuator 12x20 Uni-Module is

manufactured and inspected at our plant, then shipped to marinas

collectively where they are assembled to make our floating

breakwaters. Each with the following features:

The 20 Foot Precast Concrete Construction Allows for Anchors To Be

Installed Every 20 Feet In Both Directions, Making It The Most Reliable

System Available.

OUR WAVE ATTENUATOR 1220 UNI-MODULE HAS A PROVEN STORM

TRACK RECORD AND HAS OUT PERFORMED AND OUTLIVED ANY

PLASTIC, WOOD, ALUMINUM, STEEL OR ANY COMBINATION OF

MATERIALS THAT ARE LESS THAN AN ALL CONCRETE PRODUCT.

40,000 lbs.

per unit

From the Uni-Module floats themselves,

to the anchoring systems that secure

them, each of our products are designed,

manufactured, assembled and installed

by us.

•

Heaviest - about 2,000 Lbs. Per Running Foot.

•

Widest - 12 Feet 7 Inches With Treated Side Whalers.

•

Deepest - 7 Feet about 40,000 Lbs. Per 20 Foot Section Including Anchor Pull Down Weight.

•

Competitively Priced.

•

Concrete Encapsulated On All 6 Sides (Yes, Underneath Also!).

•

Adjustable Chain And Rope Anchor System, Designed To Absorb Wave

Energy.

•

Also Available: Adjustable Marine Winches And Cable, or Pile Guides.

•

Hydraulically Post-Tensioned Galvanized Cable System.

•

Freeboard - about 14-24 inches per 1220 unit and can vary joint to joint and ends.

•

Environmentally Friendly and Prevents Shoreline Erosion.

•

Manufactured Without Legs For Shallow Water Or Near Shore

Applications.

•

Brushed Surface That Provides A Non - Slip Walking Surface

•

Marine Polystyrene Core And A Outer Reinforced Concrete Shell.

•

Four Hydraulically Post-Tensioned Cables Run Lengthwise Through

PVC Tubing, Molded Into Each Section, To Protect The Cable Against

Corrosion.

•

All Post - Tensioned Cables And Components From End To End Are All

Above Water.

•

No Bolts, Pins Or Welded Connection Joints.

•

All Galvanized Steel Is Above Water.

•

A Proven Patented Connection Joint That Eliminates Exposure To

Sunlight And Water.

•

Four Flexible Couplers Are Between Each Unit.

•

Chain Stands On The Sides For Easy Water Fluctuation Adjustments,

And Are 12’ Apart For More Leverage, Stability And Clearance For Boat

Traffic.

•

Solar Powered Flashing Amber Lights Standard Every 30 Feet.

•

Utility Options Also Available.

•

Designed As A Commercial Marina Dock System That Has An Option

To Add Four Foot or Eight Foot Finger Piers.

•

4 Chain/Cable Anchor Bracket Locations Every 20 Feet.

•

Long Life Span With Our Three-Year Limited Flotation Warranty.

•

Pressure-Treated 4" by 6" Wooden Side Whalers Are Added As A

Standard Protection Feature.

•

Post - Tensioning of Continuous Straight Lines.

Built Stronger, Last Longer